The 4L60E is a four-speed automatic transmission widely used in GM vehicles‚ known for its durability and reliability. Transmission diagrams are essential for understanding its operation‚ maintenance‚ and repair‚ ensuring optimal performance and longevity.

1.1 Overview of the 4L60E Transmission

The 4L60E transmission is a four-speed automatic gearbox developed by General Motors (GM) for use in rear-wheel-drive vehicles. Known for its reliability and durability‚ it has become a staple in many GM vehicles‚ including trucks‚ SUVs‚ and performance cars. Introduced in the early 1990s‚ the 4L60E replaced the earlier 4L60 transmission‚ incorporating electronic controls for improved performance and efficiency. It is widely recognized for its smooth shifting and ability to handle a variety of engine torque outputs‚ making it suitable for both daily driving and heavy-duty applications. The transmission features a lock-up torque converter and a planetary gear set design‚ which contribute to its robust performance. Understanding the 4L60E’s design and functionality is essential for proper maintenance and repair‚ especially when referencing detailed diagrams. Its popularity among enthusiasts and mechanics alike underscores its importance in the automotive world.

1.2 Importance of Transmission Diagrams for Maintenance and Repair

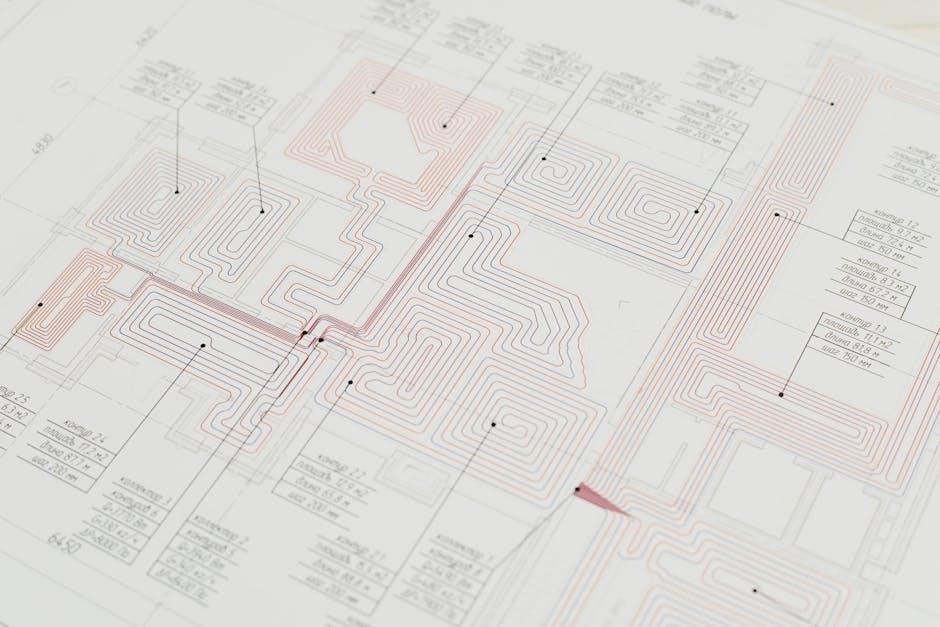

Transmission diagrams are indispensable tools for maintaining and repairing the 4L60E transmission; These diagrams provide a visual representation of the transmission’s internal and external components‚ making it easier to understand how the system operates. For mechanics and DIY enthusiasts‚ having access to detailed diagrams ensures accurate identification of parts and their relationships. This is particularly crucial when diagnosing issues or performing complex repairs‚ as it helps pinpoint potential problem areas without guesswork.

Transmission diagrams also guide the proper routing of hydraulic lines‚ electrical connectors‚ and other critical systems. They reduce the risk of errors during disassembly and reassembly‚ which can lead to costly damage. Additionally‚ diagrams are essential for troubleshooting common issues‚ such as slipping gears or faulty solenoids. By referencing a 4L60E transmission diagram PDF‚ individuals can ensure their repairs are done efficiently and correctly‚ maintaining the transmission’s performance and longevity. These resources are vital for anyone working on this popular GM gearbox.

Components of the 4L60E Transmission

The 4L60E transmission consists of key components like the torque converter‚ gear sets‚ and valve body. These parts work together to facilitate smooth gear shifts and efficient power transfer.

2.1 Key Parts of the 4L60E Transmission

The 4L60E transmission is composed of several critical components that ensure its operation. These include the torque converter‚ which transfers power from the engine to the transmission‚ and the gear sets‚ such as the sun gear‚ planet gears‚ and ring gear‚ which facilitate gear ratios. The valve body plays a central role in regulating hydraulic pressure for smooth shifting. Additionally‚ the transmission control module (TCM) manages electronic signals to control the transmission’s functions. Other essential parts are the clutch packs and bands‚ which engage and disengage gears‚ and the seals and gaskets that prevent fluid leaks. Understanding these components is vital for diagnosing issues and performing repairs effectively.

2.2 Torque Converter and Its Role

The torque converter is a critical component of the 4L60E transmission‚ serving as the link between the engine and the transmission. It is responsible for transferring power from the engine’s crankshaft to the transmission’s input shaft. Unlike a traditional clutch‚ the torque converter uses fluid dynamics to engage and disengage power smoothly. Inside the torque converter‚ there is a lock-up clutch that engages during higher speeds to directly connect the engine and transmission‚ improving fuel efficiency. The torque converter also multiplies torque during acceleration‚ providing better low-end performance. Its operation is controlled by the transmission control module (TCM)‚ which regulates the lock-up clutch engagement based on driving conditions. Proper functioning of the torque converter is essential for smooth acceleration‚ efficient power transfer‚ and overall transmission performance. Regular maintenance‚ such as checking the transmission fluid level and condition‚ helps ensure the torque converter operates effectively.

Hydraulic System of the 4L60E Transmission

The hydraulic system is essential for controlling gear shifts and clutch engagement in the 4L60E transmission. It uses pressurized fluid to activate components like clutch packs and bands‚ ensuring smooth transitions between gears.

3.1 Hydraulic Schematics and Fluid Flow

Hydraulic schematics are critical for understanding the fluid flow and pressure distribution within the 4L60E transmission. These diagrams illustrate the pathways of the automatic transmission fluid (ATF) as it circulates through the system‚ activating clutches‚ bands‚ and other components. The fluid flow begins at the transmission pump‚ which creates the necessary pressure to engage the torque converter. From there‚ the fluid is directed through the valve body and pressure regulator‚ ensuring precise control over gear shifts and torque delivery. Hydraulic schematics detail how fluid pressure is modulated by solenoids and sensors‚ allowing the transmission to adapt to driving conditions. Understanding these diagrams is essential for diagnosing issues like slipping or erratic shifting‚ as they reveal how fluid flow affects clutch pack engagement and band application. Proper fluid circulation is vital for maintaining optimal performance and preventing overheating or component failure.

3.2 Pressure Regulator and Valve Body Functionality

The pressure regulator and valve body are central to the 4L60E transmission’s hydraulic system‚ working together to regulate fluid pressure and control gear shifts. The pressure regulator ensures that the transmission operates within the correct pressure range‚ preventing damage from excessive pressure. It adjusts fluid flow based on engine load and speed. The valve body contains solenoids and valves that direct pressurized fluid to clutch packs‚ bands‚ and other components‚ enabling smooth gear transitions. Solenoids‚ controlled by the transmission control module (TCM)‚ modulate fluid pressure for precise shifting. The valve body also houses the manual valve‚ which controls the gear selector’s position. Together‚ these components ensure efficient torque transfer and optimal gear engagement. Accurate functionality of the pressure regulator and valve body is crucial for maintaining transmission performance and preventing issues like slipping or erratic shifting. Transmission diagrams provide detailed insights into their operation and interconnections‚ aiding in diagnostics and repairs.

Wiring Diagrams for the 4L60E Transmission

Wiring diagrams provide a detailed map of the electrical connections within the 4L60E transmission‚ including solenoids‚ sensors‚ and connectors. They are essential for diagnosing and repairing electrical issues‚ ensuring proper communication between components.

4.1 Electrical Connections and Pinout Diagrams

The 4L60E transmission relies heavily on its electrical connections for proper operation‚ with components like the transmission control module (TCM)‚ solenoids‚ and sensors requiring precise wiring. Pinout diagrams detail the specific functions of each connector pin‚ ensuring accurate troubleshooting and repairs. These diagrams outline the wiring harness layout‚ highlighting connections for the torque converter clutch solenoid‚ pressure control solenoid‚ and transmission temperature sensor. Understanding these connections is critical for diagnosing issues such as faulty solenoid engagement or incorrect gear shifts. By referencing the pinout diagrams‚ technicians can identify which wires correspond to specific functions‚ simplifying the process of tracing electrical faults. Properly following these diagrams ensures the transmission operates smoothly‚ maintaining optimal performance and preventing further damage. Regular inspection of electrical connections is recommended to avoid corrosion or wear that could disrupt signal transmission.

4.2 Connector Layout and Sensor Locations

The 4L60E transmission features a specific connector layout that ensures proper communication between the transmission control module (TCM) and various sensors. The main transmission connector is typically a 13-pin or 16-pin plug‚ depending on the application‚ and is located near the transmission pan. This connector links the TCM to critical components such as the vehicle speed sensor‚ turbine speed sensor‚ and pressure switches. Sensor locations are equally important‚ with the vehicle speed sensor usually mounted on the transmission case near the output shaft. The turbine speed sensor is located inside the bellhousing‚ while the pressure switches are embedded within the valve body. Understanding the connector layout and sensor locations is essential for troubleshooting electrical issues‚ as incorrect wiring or faulty sensors can lead to poor transmission performance. A detailed diagram of the connector layout and sensor positions is invaluable for technicians‚ ensuring accurate diagnoses and repairs. Regular inspection of these components is recommended to prevent corrosion or wear.

Troubleshooting Common Issues

The 4L60E transmission can experience issues like slipping‚ harsh shifting‚ or delayed engagement. Diagrams help identify problems by tracing electrical or hydraulic faults to specific components‚ ensuring accurate repairs and minimizing downtime.

5.1 Identifying Common Problems Using Diagrams

Transmission diagrams are essential for diagnosing issues in the 4L60E. By analyzing the hydraulic and electrical systems‚ diagrams help pinpoint problems like slipping‚ harsh shifting‚ or gear engagement issues. For example‚ if the transmission slips between gears‚ diagrams can trace the issue to the torque converter‚ clutch pack‚ or pressure regulator. Similarly‚ delayed engagement may indicate a faulty solenoid or low fluid pressure‚ both of which can be identified using the hydraulic schematics. Diagrams also highlight sensor locations‚ aiding in troubleshooting electrical faults‚ such as faulty speed sensors or incorrect TPS readings. Visualizing the flow of hydraulic fluid and electrical signals allows technicians to isolate malfunctions efficiently. This method ensures repairs are targeted and effective‚ reducing guesswork and saving time. Regularly referencing these diagrams helps maintain accuracy and prevents costly mistakes during diagnostics and repairs.

5.2 Diagnosing Electrical and Hydraulic Faults

Diagnosing electrical and hydraulic faults in the 4L60E transmission requires a thorough understanding of its systems and the use of detailed diagrams. Electrical issues often involve solenoids‚ sensors‚ and wiring. For instance‚ a malfunctioning shift solenoid can prevent proper gear shifts‚ while faulty sensors like the throttle position sensor (TPS) can disrupt transmission operation. Diagrams help trace these components‚ allowing technicians to test solenoid resistance or check sensor connections for faults.

Hydraulic faults typically relate to fluid pressure and flow. If the transmission slips or fails to engage gears‚ low hydraulic pressure might be the cause. Diagrams can identify components like the pressure regulator or valve body‚ guiding technicians to potential issues. By analyzing fluid flow charts‚ professionals can detect pressure drops or blockages‚ ensuring accurate diagnoses.

Cross-referencing electrical and hydraulic diagrams is crucial for comprehensive troubleshooting. This integrated approach helps pinpoint how electrical signals affect hydraulic performance‚ ensuring both systems function harmoniously. Detailed diagrams are indispensable for effective fault diagnosis‚ enabling precise and efficient repairs.

Maintenance and Repair Tips

Regular fluid checks and filter replacements are essential. Inspect for leaks and adhere to torque specifications during repairs. Use high-quality parts to ensure durability and performance.

6.1 Rebuild and Repair Information

A successful 4L60E transmission rebuild requires precise tools and a detailed diagram to guide the process. Begin by thoroughly cleaning the transmission case and inspecting all components for wear or damage. Replace seals‚ gaskets‚ and bearings as needed. The torque converter and planetary gearset often require attention. Use a rebuild kit to ensure all parts are compatible and up-to-date. Proper alignment of the valve body and pressure regulator is critical for smooth operation. Refer to the wiring diagrams to reconnect sensors and solenoids accurately. Apply even pressure when reinstalling the transmission pan to avoid damaging the gasket. Always follow manufacturer specifications for torque values and fluid levels. After reassembly‚ test the transmission in a controlled environment to ensure proper function before returning it to service. Regular maintenance and inspections can prevent future issues and extend the transmission’s lifespan.

6.2 Step-by-Step Guides for Disassembly and Reassembly

Disassembling and reassembling the 4L60E transmission requires careful planning and adherence to detailed instructions. Begin by draining the transmission fluid and removing the pan and filter. Use a socket set to remove the valve body bolts and gently lift it out. Next‚ separate the main case from the tailshaft housing‚ taking care not to damage the alignment dowels. Remove the planetary gearset and bearings‚ referencing the transmission diagram to ensure proper order. For reassembly‚ start by installing the bearings and gearset‚ followed by the main case and tailshaft housing. Reattach the valve body‚ ensuring all electrical connectors are securely plugged in. Finally‚ reinstall the transmission pan and filter‚ then refill the fluid to the recommended level. Tighten all bolts in the specified sequence to avoid warping the case. Always refer to the wiring diagrams to reconnect sensors and solenoids correctly. Proper reassembly ensures smooth operation and prevents future issues.